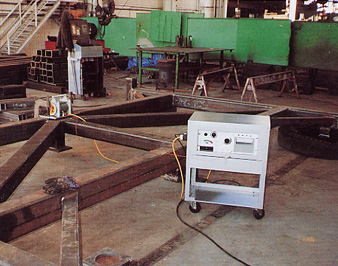

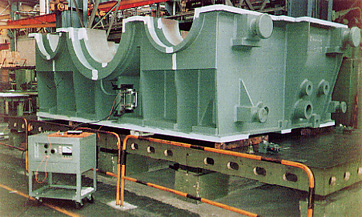

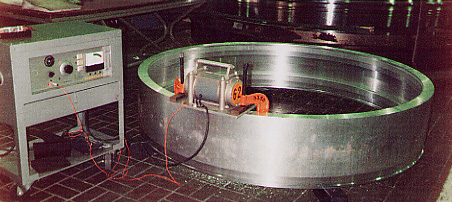

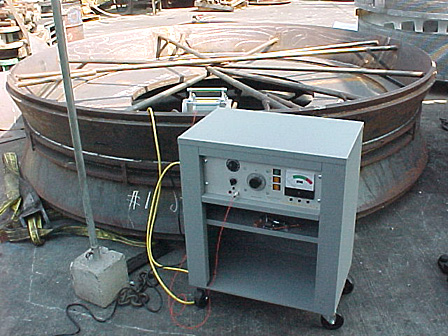

Vibratory Stress Relief - Resonant Vibration Method

for Reducing Residual Stresses in Welded or Machined Fabrications.

Stress Relief Engineering |

| Home | About Us | What is Formula 62 | Capabilities | Download Brochure | Technical Papers | Customer List | FAQ | Contact | |

|||

|

|||

| Home | About Us | What is Formula 62? | Capabilities | Customers List | Download | Technical Papers | FAQ | Contact | Site Map | |

|||

1725 Monrovia Ave. Ste. A-1 - Costa Mesa, CA 92627 - Phone: 949-642-7820 - Fax: 949-642-0430 Call Stress Relief Engineering Company Today for a free consultation! Stress Relief Engineering Co. is the world leader in vibratory stress relief technology. |

| Copyright © 2008 Stress Relief Engineering. All rights reserved. Do you have an upgrade or comment about this site? Please contact our Information desk. Site created by Web Work Connects Group - Web Development & Search Engines Marketing. |

|

FORMULA 62 Resonant Vibration Method for reducing Residual Stresses in Welded or Machined Fabrications

FORMULA 62 Resonant Vibration Method for reducing Residual Stresses in Welded or Machined Fabrications